I began the design process by first sketching it by hand, just to get an initial idea of how it would look.

This design involved approximately 300 hours of work. After finalizing what I wanted, I started the design process in Fusion 360, and this is the result I achieved as the final design. (I'm still working on some panels, but as far as the chassis design is concerned, I've decided to stick with it as my final design.)

Based on my initial design, I started by cutting the tubes and positioning them where they needed to be, then tack-welding them together. This step allowed me to get an overview of the appearance and ensure that the chassis looked good before proceeding with the full welding process. In this phase of the project, a very good friend of mine assisted me in welding the entire chassis. If you noticed, I am wearing my long-sleeve Dade Made shirt. At that time, I was still working for them and received their full support, including permission to use their equipment like welding machines, grinders, hand tools, etc.

After welding the entire chassis, I moved on to fully assemble it.

Initially, I planned to paint the chassis bronze, but then I changed my mind and opted for a matte white finish instead. These are renderings straight from Fusion 360

I disassembled the entire chassis to paint it white.

I captured a cool picture during a ride-testing session with my cousin.

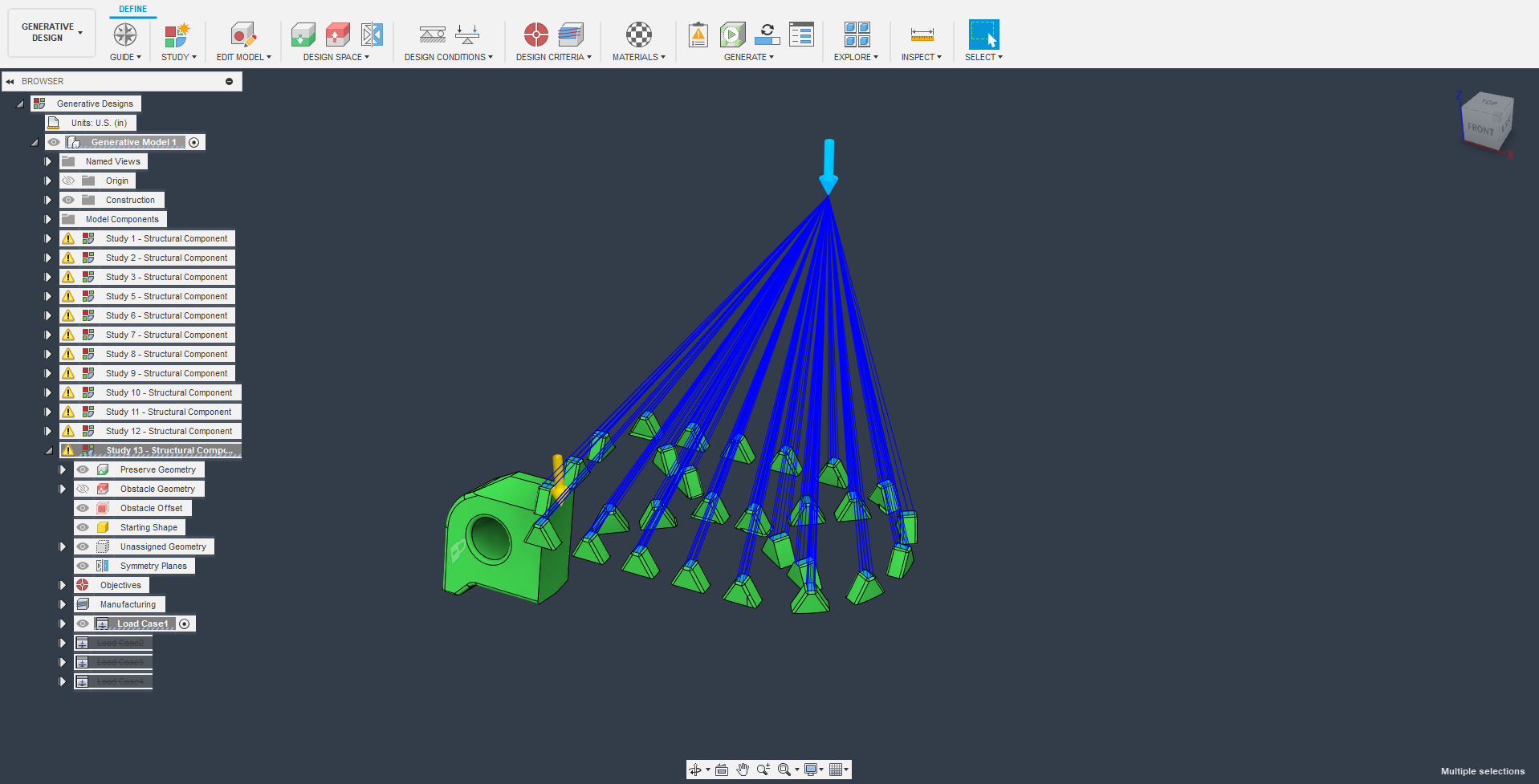

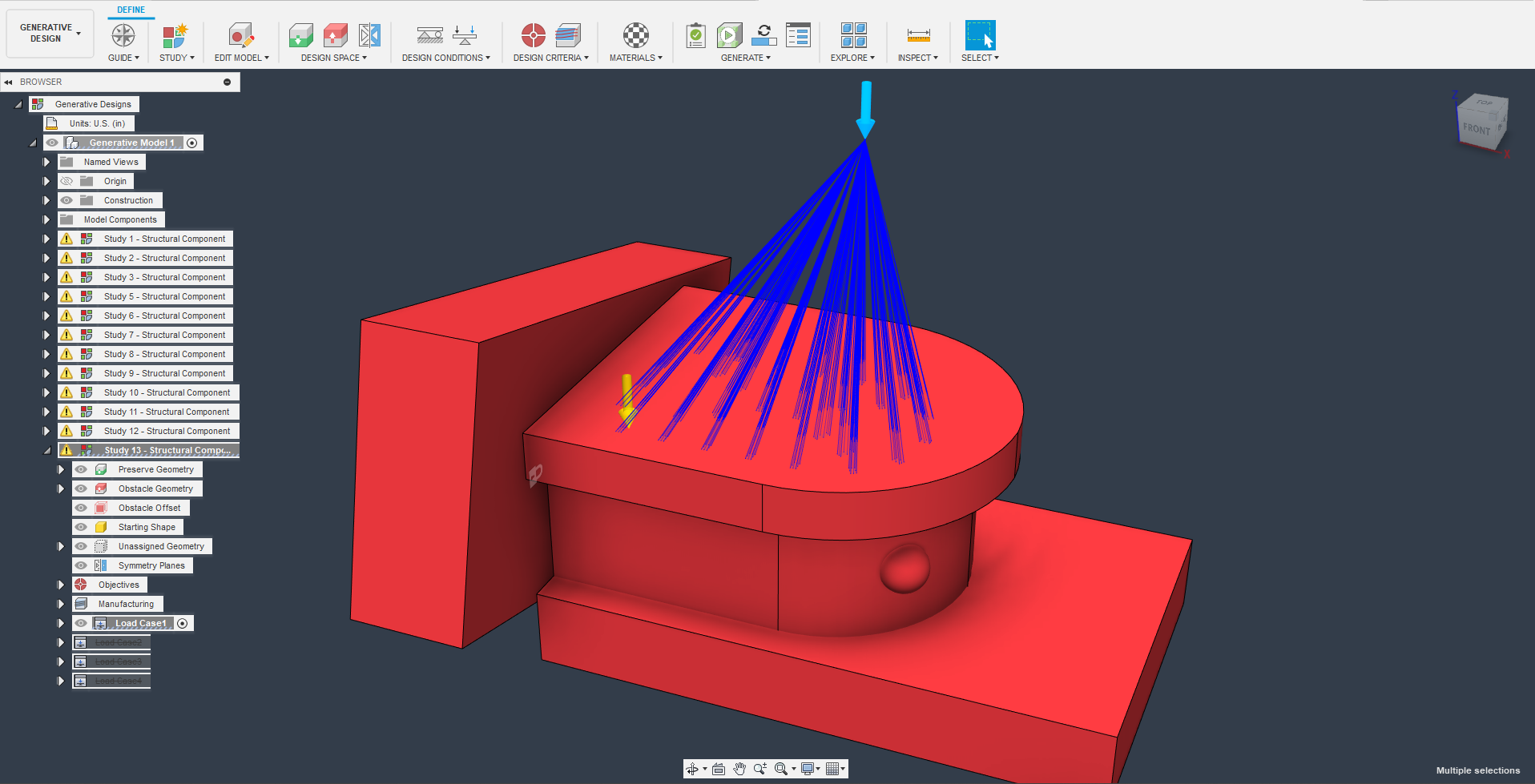

For this version of the bike, which is geared more towards off-roading, I chose to create my own foot pegs. I aimed for an organic design to impart a more aggressive appearance to the bike.

I captured a cool video of myself testing the bike on a trail.