I initiated the Formula SAE project at Miami Dade College's Wolfson Campus, assembling a team to construct a car from scratch. This endeavor aimed to provide fellow students with the opportunity for hands-on learning and experience in building a student-grade race car. Additionally, for this project, I received full support from Formula 1 and Autodesk. (To see my feature in the Miami Dade College Newspaper, please click on the first photo. For my feature on Certiport, click on the second photo. For my feature on Autodesk click on the 9th photo. )

I was given the incredible chance to present one of my Formula Style Car Prototypes to Formula 1 executives, including Richard Cregan, who is currently the CEO of the Miami F1 Grand Prix.

(Miami Dade College-Makers Lab, January 11, 2018)

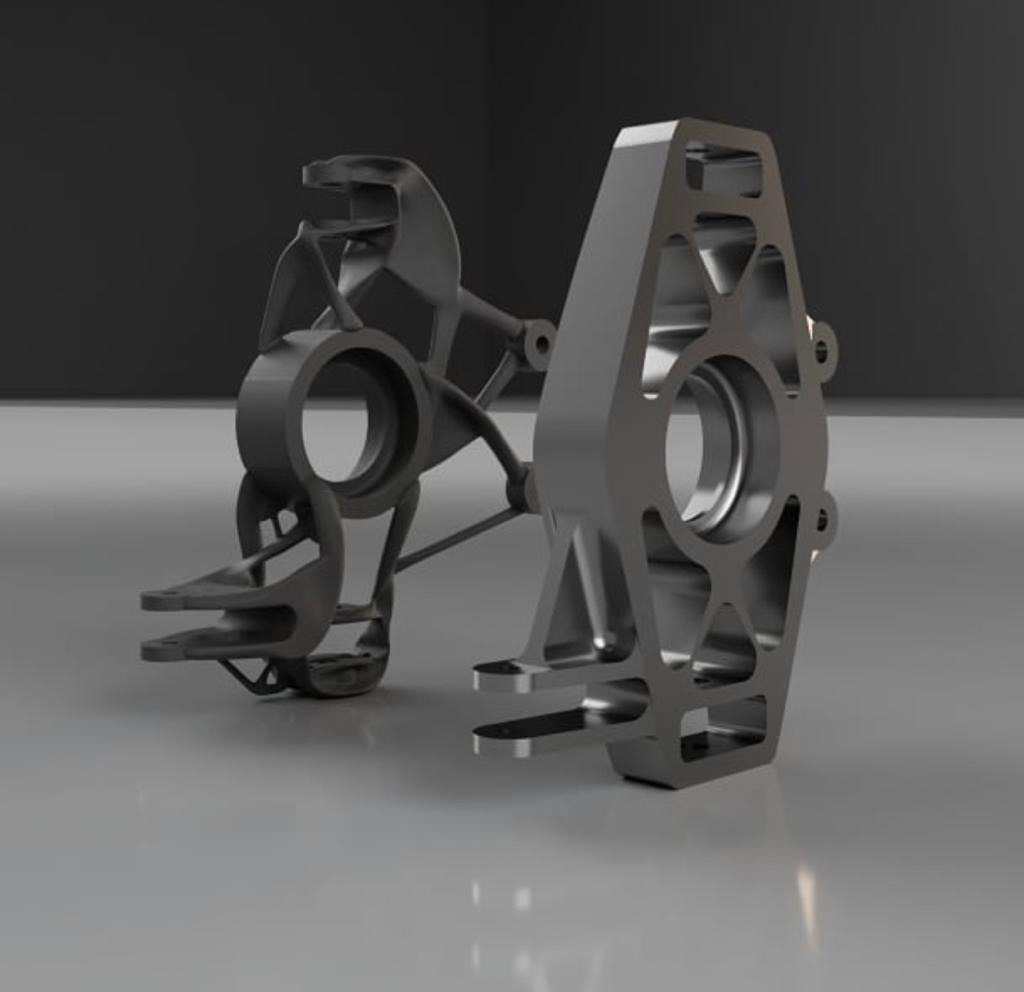

CAD Vs real life Push-Rod suspension system

I gained experience in welding steel and stainless steel at Dade Made Fabrication, where they provided support and resources for my team and me. We were given access to their equipment, enabling us to build a car from scratch. Subsequently, I joined the company as a part-time intern CAD-Drafter, where I acquired extensive knowledge about industrial design through my work on shop drawings and renderings.

I also received support from the Autodesk Technology Centre in Birmingham, UK. They 3D printed a wheel hub knuckle that I designed for The Formula SAE using Generative Design in Fusion 360. You can see the comparison between a standard design and the organic one I created.

3D Printed on the HP Fusion Jet 580 Color 3D Printer